Yes, we sell the Claw series and the S-series.

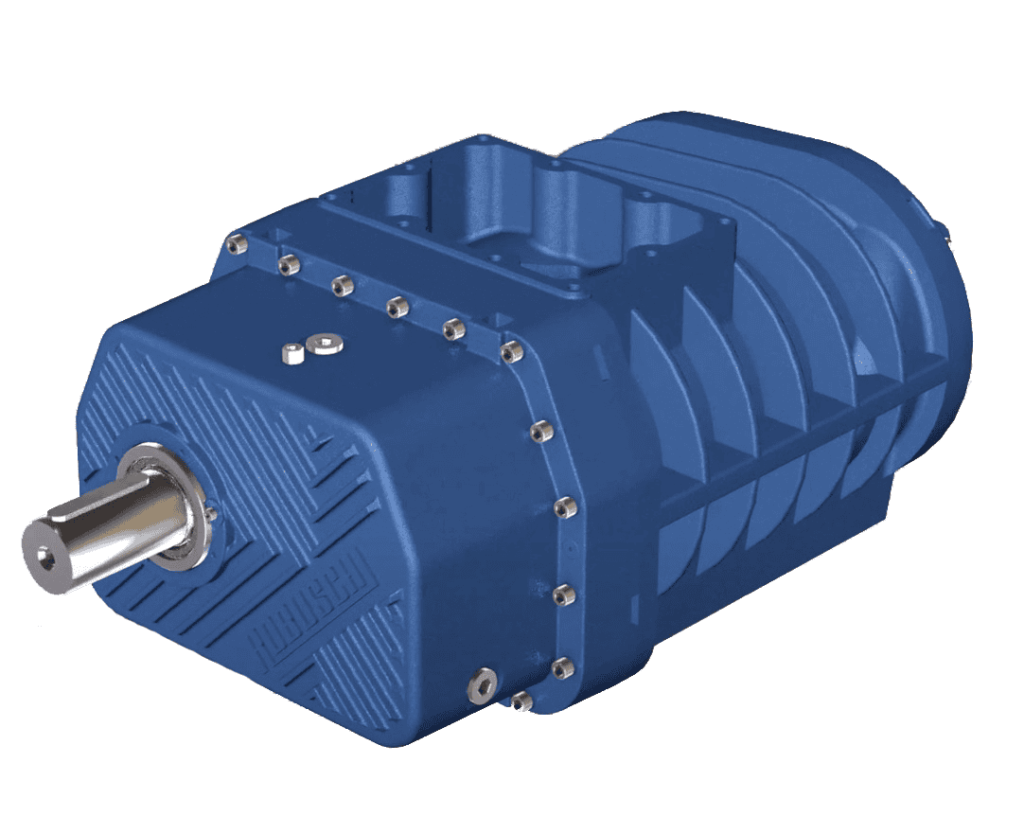

Benefits of the Claw series: The C-Series claw pumps and compressors efficiently and cost-effectively produce a contact-free vacuum or compressed air using the principle of internal compression. Gas is pre-compressed within the chamber before discharge, leading to notable energy savings compared to rotary blower designs lacking internal compression. C-Series pumps, which are dry and contact-free, employ a pair of claw-shaped rotors to generate a vacuum for diverse industrial uses, emphasizing energy efficiency and offering low-pressure solutions with high pump performance.

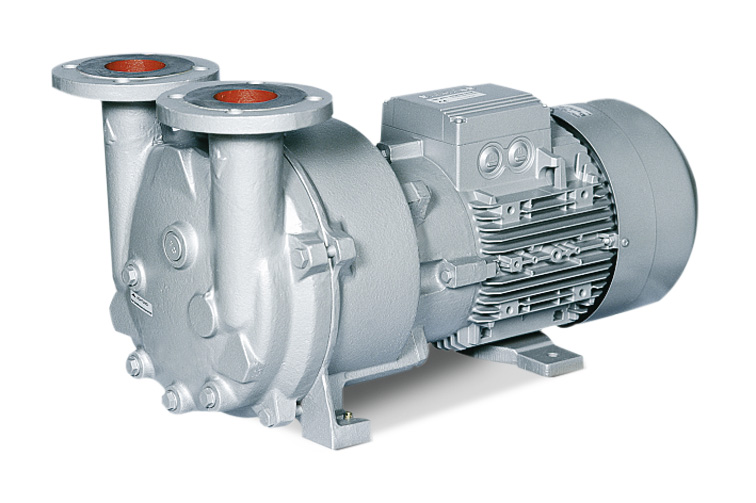

Benefits of the S-Series: The S-VSI screw vacuum pump, available in sizes 100 and 300, embodies cutting-edge dry-running technology renowned for its minimal carbon footprint and cost-effectiveness over its lifespan. Widely employed in industrial settings for tasks like drying and packaging, it offers superior performance. Meanwhile, the S-VSA and S-VSB dry-running, contact-free screw vacuum pumps find primary application in the chemical and pharmaceutical sectors for various processing needs. Ensuring freedom from oil or other operating fluids, they come in multiple sizes with ATEX certification, catering to diverse industry requirements.